Project: Custom Reversible Canvas Aprons for Front-of-House Staff

Client: Klocke Estate

Time frame: Spring 2024

WHEN THE people behind the new Hudson Valley vineyard, orchard and distillery Klocke Estate were planning their restaurant and tasting room — and were working with a variety of local artists and artisans — they came to us for custom aprons for the front-of-house staff. They were creating a highly refined, very thoughtful experience and needed aprons that were as hardworking and sophisticated as the space itself. And they wanted their commitment to sustainable farming to carry through to this project, making Made X Hudson Factory the perfect match.

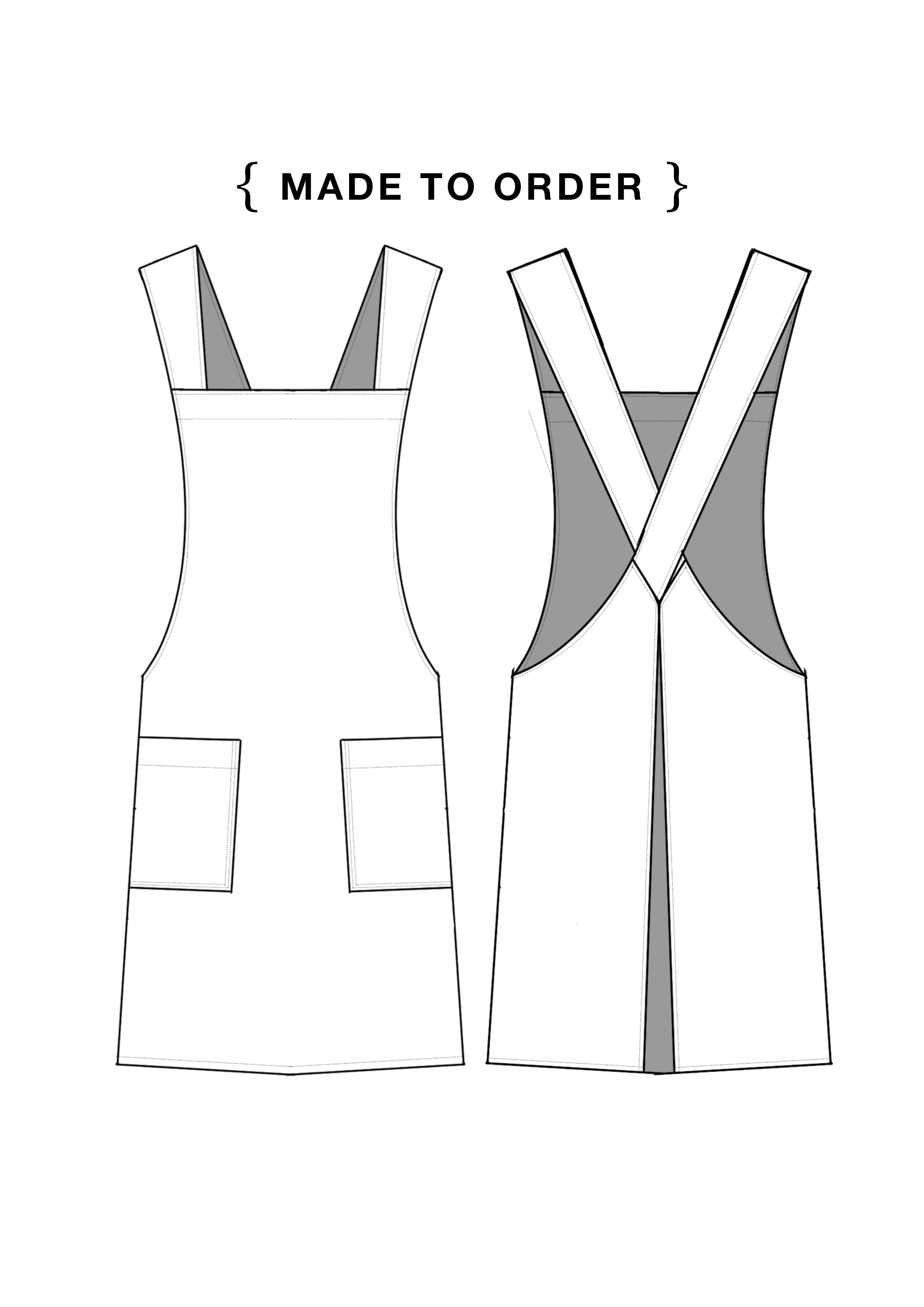

Klocke’s hospitality director, Kristine Danks, sourced navy deadstock canvas fabric and found a local leather-crafter to do the leather work on the full apron. Our co-founder and factory director, Sergio Guadarrama, worked with Kristine on the specifics of the apron design — including making them reversible, in case of a mid-shift spill — and they agreed on multiple purposeful pockets.

We talked to Kristine about how she found the process of working with us on this beautiful piece of the Klocke puzzle—

Can you tell us a bit about your brand and what inspired this project?

Whether vineyards and orchards, distillery or restaurant, Klocke Estate is all about passion, craftsmanship, authenticity and stewardship. When it came time to define the staff’s wardrobe, we knew that we would need to do something custom to find the right mix of beauty, functionality and uniqueness.

What made you choose to work with Made X Hudson for production?

For one, I lived right down the street and was falling head over heels in love with Catskill at the time. Secondly, from my first meeting with Sergio, I had deep respect and appreciation for his mastery of the process and his patience for someone who had absolutely no idea what they were doing (me). He gave great guidance and advice on the design process, materials, and worked with an ever-evolving timeline.

What was the design or development process like — any highlights or challenges?

I was both intimidated and incredibly naïve about what went into creating a custom piece. I’ve learned a lot! Challenges were getting the project to fit into my unrealistic budget. Another challenge was finding materials — how hard could it be to find beautiful, sturdy, affordable fabric in a sufficient quantity to make … as many aprons as we could afford? Very. Highlight: finding that perfect, perfect fabric. Highlight: the ability to work with another local artisan (Chris Tekverk) on the leather straps to really make this a personal piece.

How did the final product turn out, and how was it received by your customers or community?

Biggest highlight: the compliments that we get weekly on the aprons. The staff loves them (I know because they take great care of them). We get weekly compliments from our guests on them and requests to purchase them. Alas, we do not have enough to sell and will hold onto them dearly.

Any reflections or advice you'd share with other designers considering small-batch manufacturing?

It’s worth the expense in the right scenario. Ask all of the questions (even if they seem dumb) because you’re working with pros that really know their stuff.

Thank you so much, Kristine and Klocke — we look forward to future collaborations!

PLEASE NOTE: In addition to custom design and production services, all of our standard apron styles (among other things) are available made-to-order. What can we make for you?